-

Products

-

Application

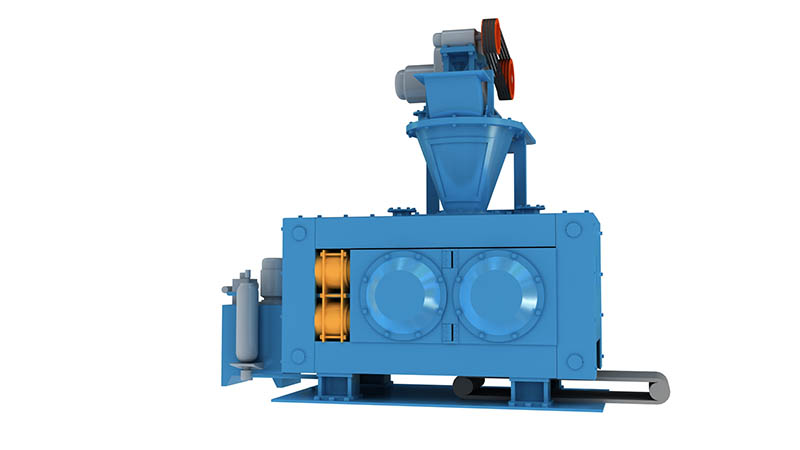

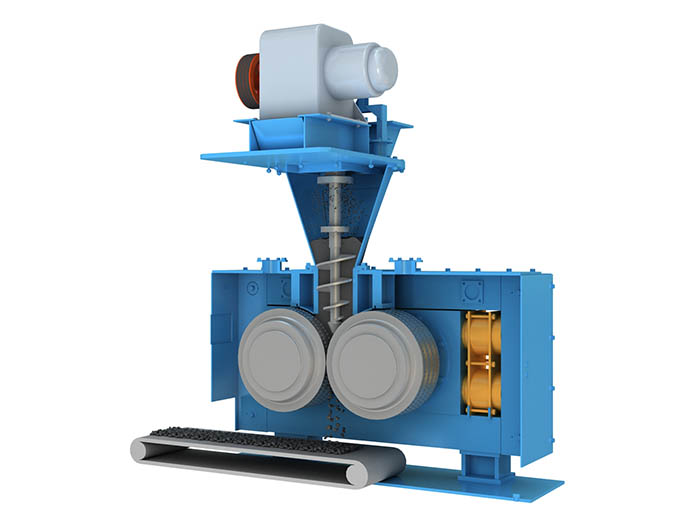

In modern industrial production, in order to save raw materials, various equipments in various industries emerge in endlessly. As an important equipment for processing and pressing and reusing, the ball press machine will inevitably have various wear and aging in use. Important work components in the ball press machine Roller skins are often replaced after being worn.

The roller skin is a cylindrical member with a ball socket dug in the outer layer wrapped around the roller core of the ball press. Usually, the pressing of the material depends on the hydraulic drive roller, which is formed by the ball socket of the roller skin, as a very easy to wear ball pressing mechanism. Frequent replacement is unacceptable to the operator, but the roller skin of the ball press after wear cannot meet the production requirements, and it ca n’t be replaced without replacement. It is very important to maintain the roller skin during use. The specific ball press What is the maintenance method of the roller skin?

There are four installation methods for the roller skin of the ball press. Different briquetting machines use different methods, but the installation standards are the same. First, the installation of the roller skin cannot be misplaced. If the roller skin is already misplaced during installation, then Not to mention the production, the shape of the ball and socket on the roller skin must be aligned, otherwise problems such as no ball, loose ball, and unrealistic spherical shape of the briquetting machine will occur; at the same time, because of the misalignment between the roller skin and the ball and socket The edges of the dimples wear on each other, and the roller skins will need to be replaced after a long period of time.

The commonly used steel for the roller skin of the casting briquetting machine is 65 manganese alloy, the commonly used steel for the roller skin of the forging ball briquetting machine is 92 chromium molybdenum. Casting roller skins are relatively wear-resistant, but they have a low cost. Some operators are not bad. It is not a problem to replace roller skins frequently. However, for operators using forged roller skins, the more durable the roller skin is, It is better not to replace, but the maintenance method of the roller skin of the briquetting machine is not allowed.

After the roller skin is installed correctly, if you want to reduce the wear of the roller skin, you must take certain protective measures before the equipment works. A magnet must be installed on the feeding belt conveyor to prevent hard metal objects from entering the roller skin and causing the roller skin to tie Injury, the staff should pick out the stones in the process of material transportation, and ensure that the particle size of the material is less than 3 mm, so that while ensuring the service life of the roller skin, it can also ensure that the material molding will not cause problems; Before that, the staff had to check the rollers of the ball press machine to see if there were any looseness or deviation. If this phenomenon continues, it is easy to break the rollers, and the loss is not only the roller skin.

The hydraulic protection device is one of the cores of the briquetting machine. While providing the required production pressure for the rollers, it can also be overloaded by the hydraulic cylinder piston rod when the feed between the roller skins or the metal block is too much. The hydraulic pump stops and the pressure changes cause the accumulator to buffer, and the overflow valve opens to return oil to displace the piston rod, thereby increasing the gap between the two roller skins. This series of actions allows hard objects to pass through the rollers to ensure the roller skins. No more serious damage.

If you want the hydraulic protection device to play its due role, you must carry out normal maintenance work. In work, the pressure supply of the hydraulic device must be reasonable, the stroke must not be excessive, and at the same time, the oil temperature of the hydraulic oil must not be too high or low. In the usual time, the hydraulic oil should be filtered regularly. If there are impurities in the oil, it is easy to damage the seal , Causing movement failure, and even the master cylinder will have scratches.

A clean production environment allows employees to ensure a positive working attitude during their work. Hygiene cleaning is required after daily work. In addition to floor cleaning, cleaning the equipment is also one of the maintenance methods of the roller skin of the briquetting machine. There is too much dust It is easy to form dust accumulation in the active parts of the equipment and the exposed bearings. If it is not cleaned for a long time, it will affect the safety and normal production, and it will also cause damage to the equipment. Some materials pressed by the ball press are corrosive, and employees are When the equipment is cleaned, the remaining materials on the roller skin and the ball socket should be cleaned up to prevent the roller skin from being corroded for a long time, which will cause damage to the roller skin.

In the daily production of the enterprise, the maintenance method of the roller skin of the briquetting machine must be correct in order to ensure that the vulnerable part of the ball press is not so vulnerable, and increase the benefit of the enterprise in disguise. It is the equipment maintenance methods.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com

Official Agent of ZY MINING in Russia.

Please enter here.

Add: Luoxin Industrial Zone,Luoyang City,Henan Province P.R.C.

Tel: +86-379-67313306

E-mail: gloria@zyksjx.com